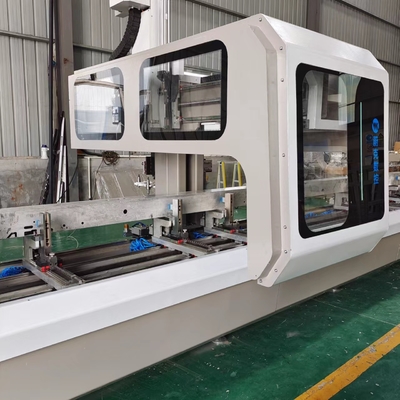

The 4 machining centre with 4 axes has been designed to carry out drilling and milling operations on aluminium or steel profiles. Because of the solutions used in its construction, WSJ4 is suitable to machine large section profiles. The 24,000 rpm, 9.6 kW electrospindle allows removal of a significant amount of chips and high machining speeds.

![]()